Steven J Trzepacz, OD

223 E Main St Streator, IL 61365 815-673-1591

Lens Options

Lens materials:

Glass: The original lens material, glass is rarely used today. The advantages of old fashioned glass lenses are extreme scratch resistance, and thin lenses with high optical clarity. But the disadvantages are heavy lenses, high prices, long wait to make them, and easily shattered and unsafe.

Plastic: The most popular lens material is plastic 1.50. Treated with front and back surface scratch resistance, it is one of the most inexpensive, durable and reliable materials. The disadvantages of plastic occur with higher powers. They can become thick and heavy. The impact resistance is also not recommended for children, sports and safety glasses.

Polycarbonate: A higher index than plastic (1.54), polycarbonate lenses have the highest impact resistance of all materials. Polycarbonate or Trivex is recommended for all children, sports and safety glasses. The higher index results in an inexpensive improvement in thickness and weight compared to plastic. Although improving every year, polycarbonate is a newer, less reliable material compared to plastic. Lenses can craze after 2 years.

Trivex: A newer, higher quality version of polycarbonate. Trivex is the only material we will use on drill mount frames.

Hi-Index Plastic: Newer plastic materials have been developed with higher indices. The higher the index, the thinner and lighter weight the lenses will be, and the more expensive they will be. The higher the patient's prescription is and the size of the frame will determine how much benefit will be achieved by each index.

1.50 1.60 1.67 1.74

The picture to the left represents the same power lens in the same frame with different lens materials. The Hi-Index 1.74 is almost half as thick as the Plastic 1.50!

From left to right: -6.00D Power

Plastic Hi Index 1.60 1.67 1.74

Aspheric Design: For a small fee, most Hi-Index lenses can be made in an aspheric design. This will improve the look and thickness of the lenses, and will produce a less distorted image.

Lens Treatments:

Lens Treatments:

Ultraviolet (UV) Coat: A UV coat will absorb harmful UV rays. This is highly recommended on all plastic lens sunglasses, or patient's who have any diseases that can be worsened by UV rays, such as Macular Degeneration. UV absorption is naturally inherent in Hi-Index materials, so no additional coating is necessary.

Basic Factory Scratch Resistance: This only covers the front surface of the lens. We add a dip coat to the back surface for extra protection, and provide a one year one time replacement warranty for front or back surface scratches.

Deluxe Scratch Resistance: TD2 coated lenses come with an unlimited 2 year warranty against scratches on the front or back surface of the lenses.

Lens Styles:

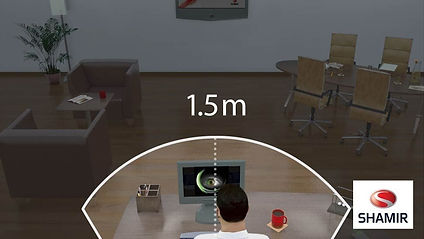

Computer Only Lenses: Computer usage has put great strain on our eyes in today's society. Bifocals and progressive lenses require difficult head tilts and turns, resulting in back and neck aches and headaches. Several computer only lens styles are now available. Make work enjoyable with a specialized pair of occupational glasses.

Shamir Computer Lenses

Shamir Workplace Lenses

Prescription Sunglasses:

Prescription Sunglasses:

Basic Tint: The most popular and inexpensive prescription sunglass, plastic lenses can be dipped to any color and density of sunglass. It is highly recommended to add a scratch resistant coating and UV coating.

Polarized Lenses: The highest quality sunglass, a polarized lens will cut annoying glare. These are great for driving in the snow, snow skiing, water skiing, fishing and boating. Adding an anti-glare coating is also an option.